What Are You Looking For?

Zinc powder coating is an anti-corrosive primer, designed to protect steel substrates.Used in a two-coat system, zinc powder coating forms a resilient base layer.For exterior use, you will need to then apply a second layer which will be a polyester powder coating.

Brand :

WananMOQ :

100 KGSShelf time :

9 MonthLead time :

7 days-15 daysPlace of Origin :

Fujian,ChinaMain Raw Material :

Epoxy Resin/Polyester ResinAnti Corrosion Base Coat Zinc Rich Powder Coatings

Zinc powder coating is zinc-rich. That means it has a metallic zinc content above a certain level.It is a form of epoxy zinc paint where, besides zinc, there are two key elements; epoxy resin and a hardener.

Epoxy has a proven chemical resistance which makes it ideal for sealing steel, concrete and other industrial materials.

Zinc powder may be applied as a stand-alone coating, but only for internal use, but typically it works as an undercoat, providing additional protection from corrosion beneath a topcoat.

Quick Details

| Appearance | Smooth finish |

| Color | RAL or Pantone or Customization |

| Film Thickness | 80-90μm |

| Curing Condition | 190℃(Object temperature) for 15 minutes |

| Impact Resistance | Direct & Indirect 50kg/cm |

| Pencil Hardness | 2H |

| Flexibility | 6mm Mandrel |

| Salt Spray Test | 5% NaCl Solution for 500 hours - No change |

| Acid Resistance | 5% HCL for 48 hours dip test - No change |

| Alkali Resistance | 5% NaOH for 48 hours dip test - No change |

| Package | Carton packing with PE bag,net weight is 20kg or 25kg each carton. |

A multi-coat system for coating substrates helps bolster protection against corrosion.Corrosion will strike at weak points in a coating system, and will exploit those aspects where a design is weakest such as:

Poor air circulation

Corners and sharp edges

Unsealed hollow sections

Depressions and crevices

Ledges

Even the most expertly fabricated parts are likely to have sharp edges, for example, that are weak points.

A multi-coat system, using zinc powder coating as a base, will provide a higher level of protection at these sharp edges and other intrinsically weaker points in a fabrication.

Applying an undercoat will help protect against corrosion, provide good mechanical and chemical resistance and supply a resilient base layer upon which you can then apply a topcoat of your choice.

WHY CHOOSE WANAN

Fujian WANAN Industry Group Co.,Ltd. is a high-tech enterprise which specializing in manufacturing thermosetting powder coating.

Founded in January of 1996 and after more than 27 years developing,we already became one of the top manufacturer which focusing on research,developing manufacturing and sales.

Our powder coatings had gained a great reputations from both home and abroad,we have approved by ISO 9001:2015,ISO 14001:2015,ISO 45001:2018,IATF 16949,CNAS and QUALITOAT.

Our brand stable quality,well coating ability,strong impact resistance,strong adhesion,perfect weather resistance property and large painting area.WANAN brand keep Top 3 in China since 1996.

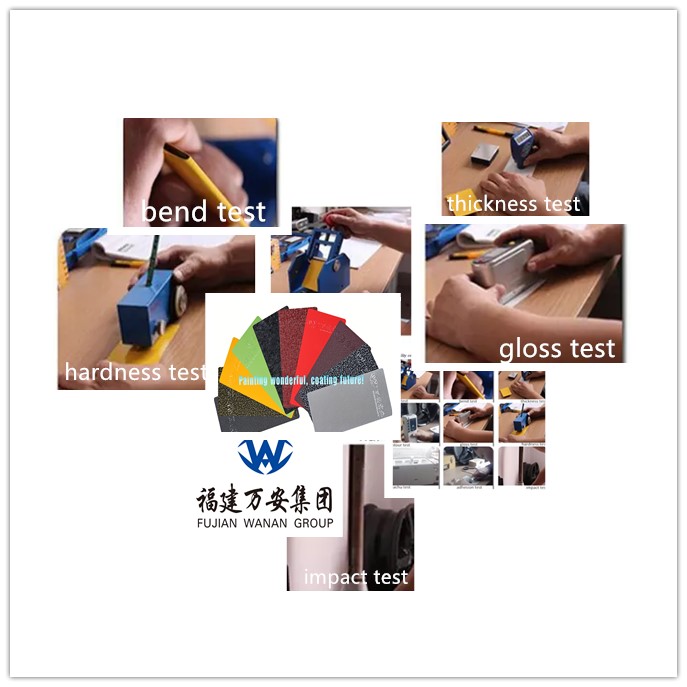

QUALITY CONTROL

There are certain specific tests for powder coatings and for the cured coating. Once powder coating is delivered to the end user, it can’t be adjusted like a solvent based paint. Therefore extremely strict quality control must be exercised by the powder manufacturer during all stages of the manufacturing process.

FAQ

Q1: Are you factory or trading company?

A1: We are professional powder coating factory with more than 600 employees.

Q2: Where is the location in China?

A2: Our company headquarter is located in ZhangZhou city,Fujian province,China,30mins distance to Xiamen port.

Q3: Can you provide samples for quality checking before place order?

A: Samples are avaliable upon request,but the shipping cost will be bear by customer.

Q4: Is there a discount price?

A: Of course,bigger quantity will be bigger discount.

Q5: How about leadtime?

A:Estimate lead time: About 7-15 working days after payment confirmed.

Q6:Are there powders for interior or exterior use?

A:It is depend on client's requirement.

Q7:How many colors do you have?

A:RAL,Pantone or any customization color is available.

Q8:Do you have any available powder coating stock?

A:Yes we stock more than 400 of popular colors or contact us to order specific color that you need.

Q9:How should I store powder coating well?

A:Store at room temperature(30℃),keep cool,dry and away from direct sunlight.