What Are You Looking For?

Electrostatic spraying can give parts better appearance quality and strong environmental adaptability, and has been widely used in the coating industry.

It has significant advantages over traditional painting processes: no primer, no thinner; No pollution to the environment, no toxicity to the human body; The construction is simple, and there will be no sagging phenomenon common in the painting process; The appearance quality of the coating is excellent, the adhesion and mechanical strength are high, and the corrosion resistance and wear resistance are strong; Short curing time, high production efficiency and low cost.

Although the surface quality of the substrate has been fully considered at the beginning of the design structure and process of the radar parts, the coating quality is affected due to the inherent defects of the non-processed surface, the processing defects of the processing surface, and the bumps and extrusion defects caused by the transfer process, and it is necessary to fill the conductive putty.

1. The main factors affecting the quality of electrostatic spraying of parts

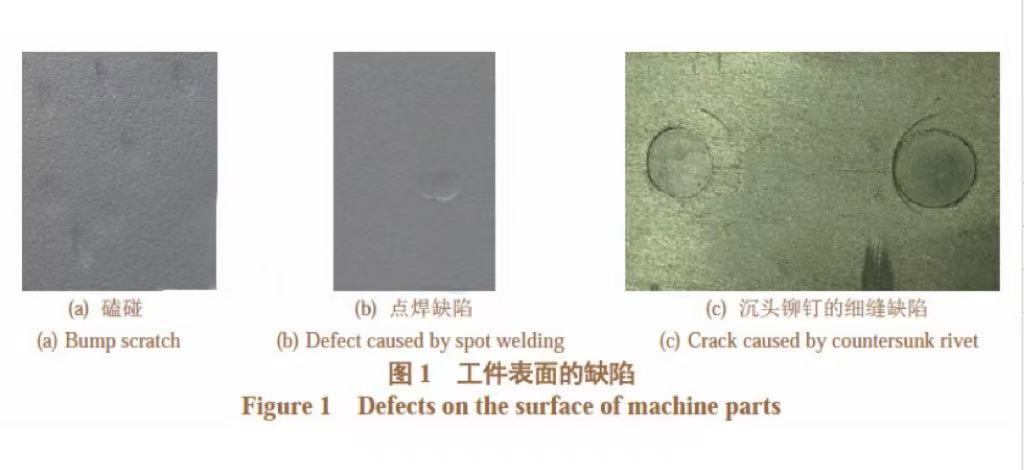

The main factor affecting the surface quality of electrostatic spraying is the defects of the parts themselves, which are mainly reflected in the pits formed by scratches, extrusions, bumps, rusts, spot welding, riveting, etc., as well as the sand holes, pores, loose and small knife lines exposed after machining of castings. As shown in Figure 1, some of these defects can be repaired by means of polishing and sanding, while others can only be filled with conductive putty. And because the composition of conductive putty is basically similar to ordinary putty, it also has the disadvantages of ordinary putty. The main manifestations are: poor adhesion and low bond strength; The surface is not delicate enough, the texture is poor, and the toughness is lacking; It is easy to pulverize after moisture; After a certain period of time, cracking, peeling, and falling off will occur. In addition, the skill level of the operator, the quality of the electrostatic powder, the performance of the equipment, the operating environment, the processing process, etc., will also affect the quality of the electrostatic spraying of parts.

2. Idea and comparative test to improve the performance of conductive putty

Analyzing the above many factors, most of them can be effectively solved by modifying the design, improving the process, operating training, improving facilities, meticulous turnover, etc., only the performance of conductive putty can not be controlled. Because it must have good conductivity, excellent adhesion, strong filling, high temperature resistance of 180 °C and other characteristics, and the conductive putty currently sold on the market is difficult to fully meet the use environment and technical requirements of existing products. To this end, the author has made some attempts and comparisons in long-term production practice, hoping to improve the performance of conductive putty through some technical means.

2.1 The method to improve the performance of conductive putty

First, consider using a finished conductive putty. However, commercially available conductive putty often has poor conductivity, low powder rate, and unsatisfactory coating effect. So can a certain proportion of conductive material be added to the conductive putty to improve its conductivity and powder rate?

Second, consider adding a conductive material to the adhesive so that it is both fillable and conductive. But when a conductive material is added to the adhesive, it will definitely destroy its adhesion and reduce its adhesion, so how much will this affect the coating?

In addition, consider using acetone to adjust the paint into a powder slurry and then apply it to the defect with a brush. But the question is whether the paint will blister under high temperature baking after containing a certain amount of acetone?

2.2 Test protocol

According to the above ideas, three schemes to fill the defects were designed by using the existing materials:

(1) Add an appropriate amount (5%~10%) of aluminum powder after fully stirring the commercially available conductive putty to improve its conductivity. If it is a two-component putty, it needs to be scraped as soon as possible, and it must be used up within the gel time to avoid thickening and agglomeration.

(2) Choose a variety of adhesives with good resistance to media (such as oil, water, acid, alkali, etc.), strong adhesion to metal, low temperature drying, high temperature use, non-toxic, and cheap adhesives to add conductive aluminum powder.

(3) Take the powder used in the workpiece and mix it into a powder slurry with acetone. It should not be too thick to avoid leaving brush marks; It should also not be too thin, otherwise the solids content is too small to fill the defect. Generally, it is more appropriate to control the solid content at 60%~65%, and then apply the brush to the defect with a brush and bake it in an oven at 180°C for about 30min.

2.3 Test Results

According to the above three schemes, the comparative test of electrostatic spraying was carried out on some specimens with similar surface defects.

Test process: degreasing, rust removal→ drying→ putty-coating→ drying→ grinding→ soot blowing→ powder spraying → curing.

After adding a small amount of aluminum powder to the commercially available conductive putty, the adhesion between the putty and the workpiece decreases significantly, and the increase in solid content makes it difficult to scrape, while the conductivity is slightly improved but still not ideal. Although the putty prepared with adhesive has good conductivity, the adhesion is poor, and due to the addition of a certain amount of aluminum powder, the putty prepared has the phenomenon of pulverization, which is prone to cracking, blistering, falling off, etc.

The filling property of the putty made by scheme 3 is too poor, and it needs to go through many times of "brushing→ spot coating→ baking → grinding" to achieve the filling effect, although the conductivity is good, but the blistering is serious.

It can be seen that all three options are not ideal. After careful analysis, it is believed that the main reason for the coating defects is that the inherent physical and chemical properties of the original material have been artificially changed, and although the conductivity effect has been improved, the adhesion, delicacy, and operability are obviously damaged, so we can only seek a breakthrough from the physical aspect.

3. The method of making self-made conductive putty with powder coating

Recalling that when grinding and reworking some sprayed workpieces, it was found that the original defects such as small pits, cracks, and sand holes on the surface of the workpiece were often not as obvious as before. Could it be that the coating that is not easy to sand off at the defect plays the role of putty? Therefore, it was considered to use the molten powder coating directly as a conductive putty.

3.1 Filling of defects such as sand holes and knife lines in large areas

In order to achieve the best filling effect, a thicker coating must be obtained at the defect, and preheating the workpiece can significantly increase the thickness of the powder coating, as the resistance of the powder tends to decrease as the temperature increases. When the temperature of the workpiece increases, the amount of charge neutralized by the powder through grounding discharge will increase accordingly, and the charge accumulation will be reduced, so the powder layer can be adsorbed thicker. In actual operation, the workpiece is often preheated first, and then thermal spraying, and then polished with tools such as grinding machines and polishing machines, and grinding until the non-defective parts are faintly exposed to the bottom layer of the metal, and the powder coating left by the defective places plays the role of putty.

3.2 Filling of local defects

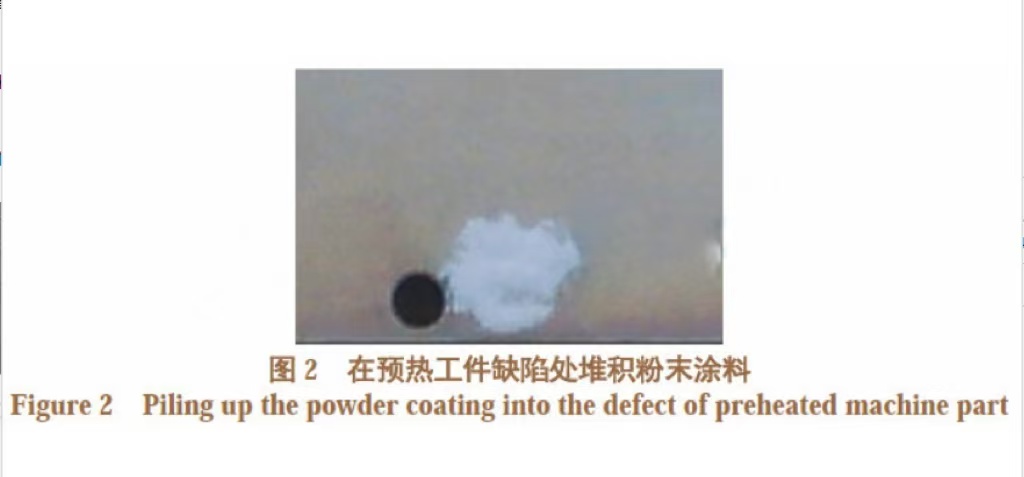

The overall grinding amount of the workpiece is large after spraying, and the powder coating is seriously wasted, so the scattered small area defects should be partially filled with powder. First of all, the workpiece should be preheated, and the preheating temperature should be 20~30°C higher than the normal curing temperature of the powder coating. Make the defect surface level upward, immediately scoop the powder with a small utensil such as an ear picker, and pile up locally at the defective place, and strive to be accurate when stacking, and try not to exceed the defect range too much, as shown in Figure 2. The powder used should be of the same brand, model, color and batch as far as possible with the powder to be sprayed at the end.

Immediately afterwards, the workpiece is placed horizontally in the oven. In order to avoid the aging of powder coating caused by multiple baking, the baking temperature should be 20~30 °C lower than the normal curing temperature of powder coating, and the baking temperature should be about 15min. If it is a sand hole of a casting, the workpiece should be taken out after baking for about 10min, and a small scraper should be used to scrape the molten powder to squeeze it into the depths of the sand hole to exhaust the air, so as to avoid bubbles after the final overall spraying, and then put the workpiece into the oven to continue to solidify after scraping. After curing, the workpiece is cooled and sanded with 240# abrasive cloth. If the defect is not even, repeat the above process once. Since this method is mainly suitable for workpieces with small defects such as spot welding, sand holes, scratches, etc., it is usually enough to fill the defects with 2 times of composting.

Repeated tests under different types, different brands, different colors, different gloss, different temperatures and other conditions show that the method of local accumulation of powder coating at the defect of the preheated workpiece has good filling, good repair effect on various fine defects, and good conductivity, excellent powder absorption, uniform powder loading during the overall spraying, and does not affect the performance of the final powder coating film.