What Are You Looking For?

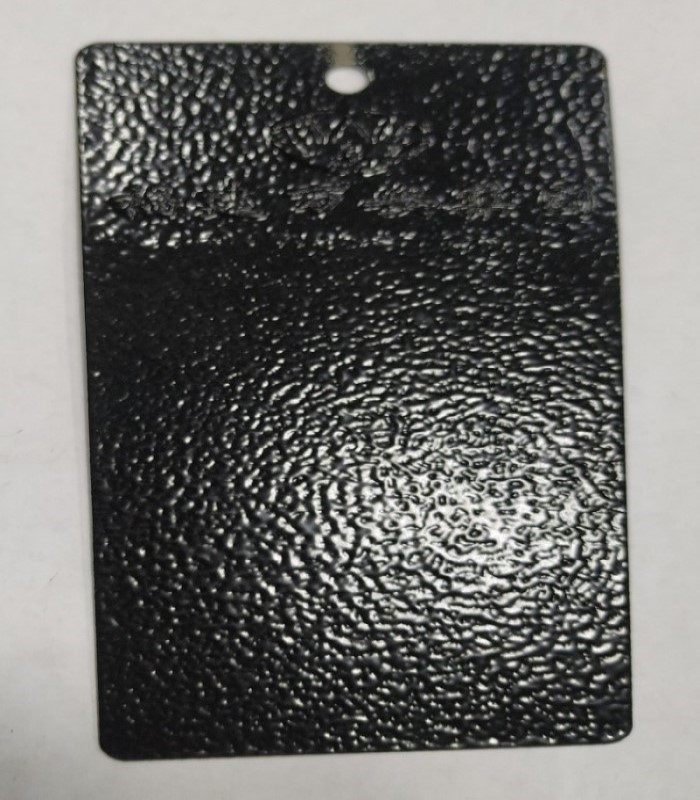

Most of the time, what it comes down to is what your customer wants aesthetically. Perhaps they need a rusty looking finish, or a rough texture, or an extra something to make the part stand out from the crowd. It is usually driven by the customer needing a specific aesthetic, or designers aiming for particular looks. However, the need for a special effect could also come from the need to hide a substrate surface that doesn’t look good. This is the main functional reason for using them.

Brand :

WananMOQ :

100 KGSShelf time :

9 MonthLead time :

7 days-15 daysPlace of Origin :

Fujian,ChinaMain Raw Material :

Epoxy Resin/Polyester ResinWrinkles offer a very specific look. Smooth, classy and sophisticated, wrinkles are a comparatively mild special effect that can add real depth to a color and are pretty good at hiding the substrate. Not only are they a great visual effect but they also have decent weathering, good hardness, corrosion resistance, chemical resistance, and they are a great special effect for covering up surface imperfections.

Quick Details

| Appearance | Wrinkle finish |

| Color | RAL or Pantone or Customization |

| Film Thickness | 80-90μm |

| Curing Condition | 190℃(Object temperature) for 15 minutes |

| Impact Resistance | Direct & Indirect 50kg/cm |

| Pencil Hardness | 2H |

| Flexibility | 6mm Mandrel |

| Salt Spray Test | 5% NaCl Solution for 500 hours - No change |

| Acid Resistance | 5% HCL for 48 hours dip test - No change |

| Alkali Resistance | 5% NaOH for 48 hours dip test - No change |

| Package | Carton packing with PE bag,net weight is 20kg or 25kg each carton. |

The key to a good wrinkle is preparation. Have a good pre-treatment system in place. No matter if you shot blast or use chemical pretreat, keep it consistent across the board. Clean all contaminants, especially oil, from the part and ensure the pretreat is applied evenly as any dirt or contaminants can interfere with how the wrinkles form.

Next, depending on whether you use a batch oven or automatic system, you need to be sure that it is a conventional fire oven. You need to be able to ramp up the temperature quickly at the start of the cure cycle to ensure consistent wrinkling in the coating. In our general experience working with wrinkles in an infrared oven can be extremely tricky and is best avoided!

As for the actual application, it applies like any other powder. The trick is to settle on a film thickness that achieves the effect you and your customer want, as a thinner film may not wrinkle to the same degree as a thicker film. Be certain to always refer to the Technical Data Sheet for accurate thicknesses and cure times.

WHY CHOOSE WANAN

Fujian WANAN Industry Group Co.,Ltd. is a high-tech enterprise which specializing in manufacturing thermosetting powder coating.

Founded in January of 1996 and after more than 27 years developing,we already became one of the top manufacturer which focusing on research,developing manufacturing and sales.

Our powder coatings had gained a great reputations from both home and abroad,we have approved by ISO 9001:2015,ISO 14001:2015,ISO 45001:2018,IATF 16949,CNAS and QUALITOAT.

Our brand stable quality,well coating ability,strong impact resistance,strong adhesion,perfect weather resistance property and large painting area.WANAN brand keep Top 3 in China since 1996.

QUALITY CONTROL

There are certain specific tests for powder coatings and for the cured coating. Once powder coating is delivered to the end user, it can’t be adjusted like a solvent based paint. Therefore extremely strict quality control must be exercised by the powder manufacturer during all stages of the manufacturing process.

FAQ

Q1: Are you factory or trading company?

A1: We are professional powder coating factory with more than 600 employees.

Q2: Where is the location in China?

A2: Our company headquarter is located in ZhangZhou city,Fujian province,China,30mins distance to Xiamen port.

Q3: Can you provide samples for quality checking before place order?

A: Samples are avaliable upon request,but the shipping cost will be bear by customer.

Q4: Is there a discount price?

A: Of course,bigger quantity will be bigger discount.

Q5: How about leadtime?

A:Estimate lead time: About 7-15 working days after payment confirmed.

Q6:Are there powders for interior or exterior use?

A:It is depend on client's requirement.

Q7:How many colors do you have?

A:RAL,Pantone or any customization color is available.

Q8:Do you have any available powder coating stock?

A:Yes we stock more than 400 of popular colors or contact us to order specific color that you need.

Q9:How should I store powder coating well?

A:Store at room temperature(30℃),keep cool,dry and away from direct sunlight.